What is TPE (Thermoplastic Elastomer)?

Thermoplastic elastomers are defined in the ASTM D1566 standard as "a group of rubber-like materials that, unlike vulcanized conventional rubber materials, can be processed and recycled like thermoplastic materials." Thermoplastic Elastomers do not require curing or vulcanization during processing and can be processed with traditional thermoplastic techniques such as injection molding, extrusion, and blow molding.

What is a Polymer?

It is necessary to explain some basic points before providing detailed information about Thermoplastic Elastomers (TPE).

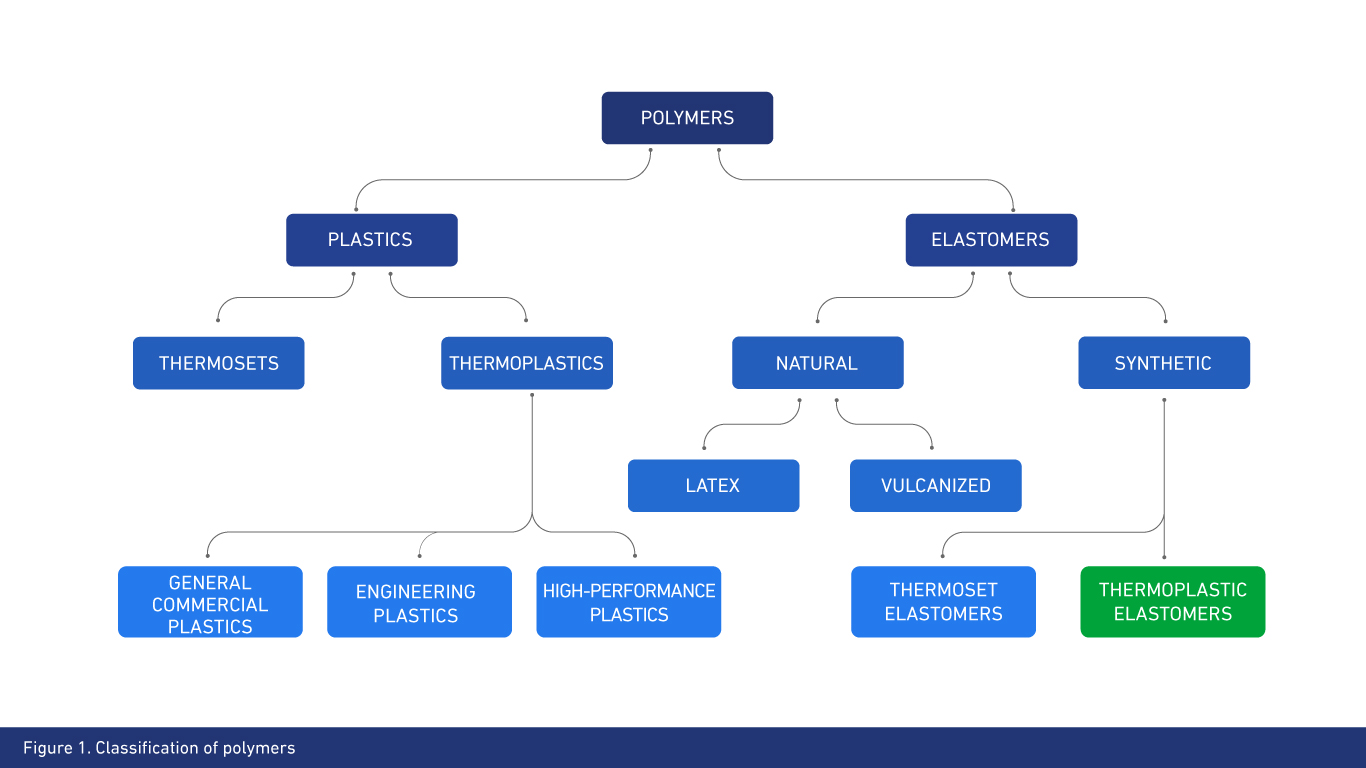

A polymer is a large molecule made of repeating small and simple chemical units. They are classified as follows according to their formation ability. TPEs (thermoplastic elastomers) belong to the elastomer class.

Position of TPEs in Polymeric Materials Group

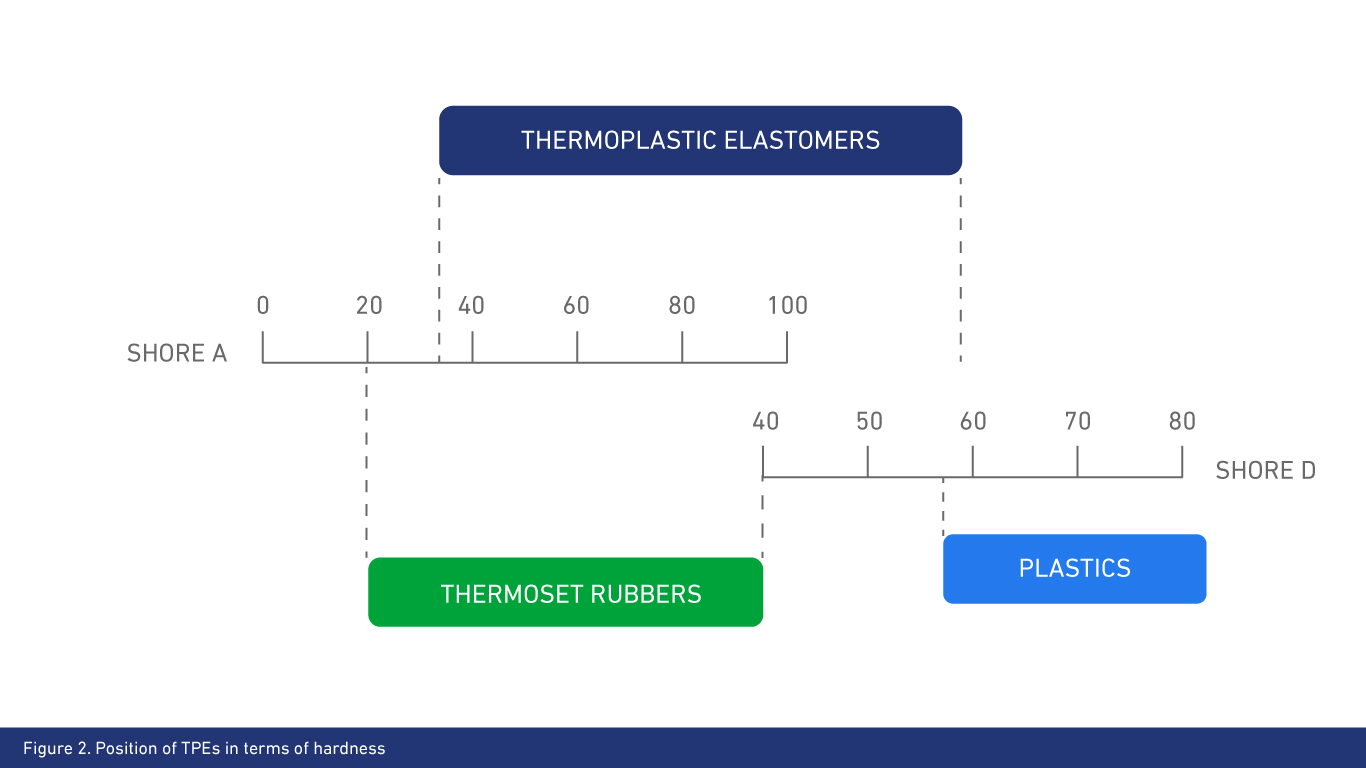

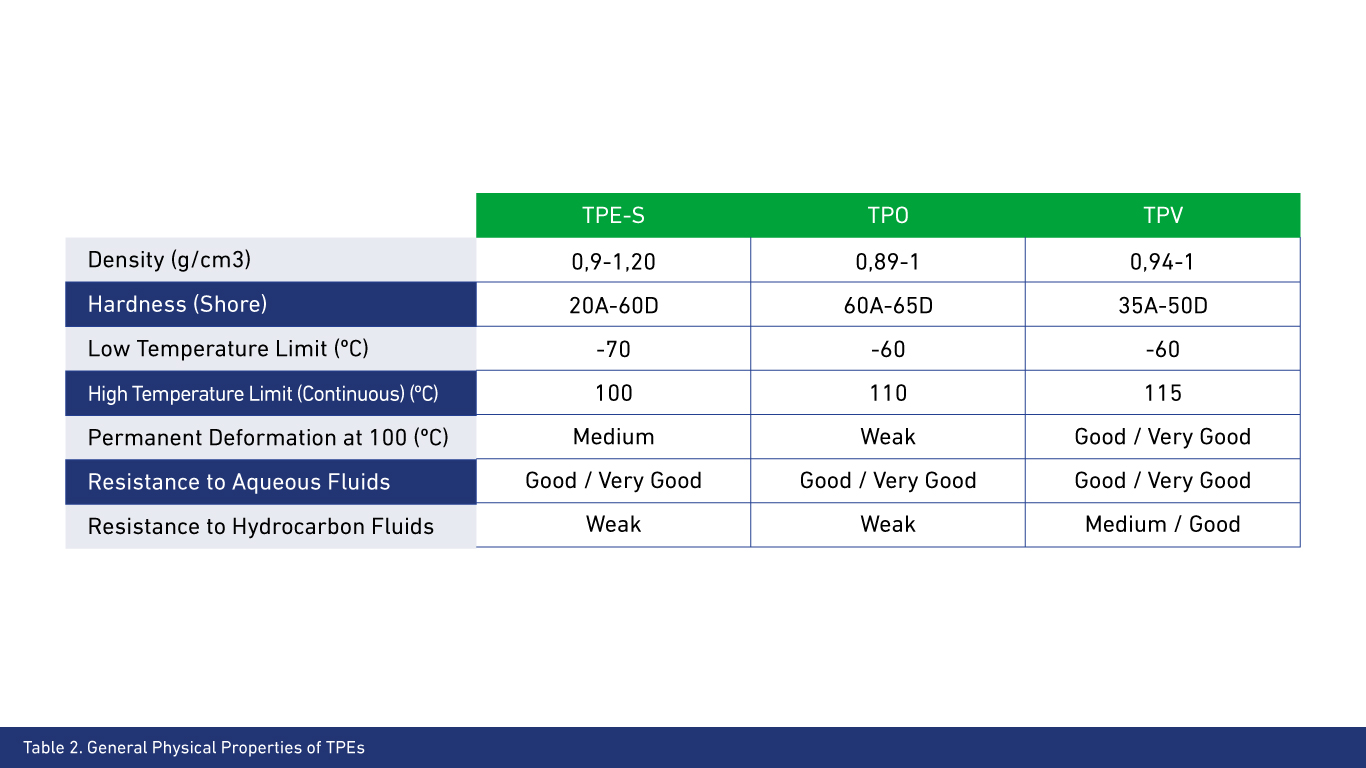

There was a clear distinction between rubber and plastics before TPEs were introduced. Rubbers are soft, flexible, and elastic, whereas plastics are known to be hard and rigid. TPE materials can be processed and recycled like thermoplastics but they have similar properties and performance to thermoset rubber materials. The best way to classify TPEs in polymeric materials is to evaluate them in terms of hardness (Figure 2).

Classification of TPEs

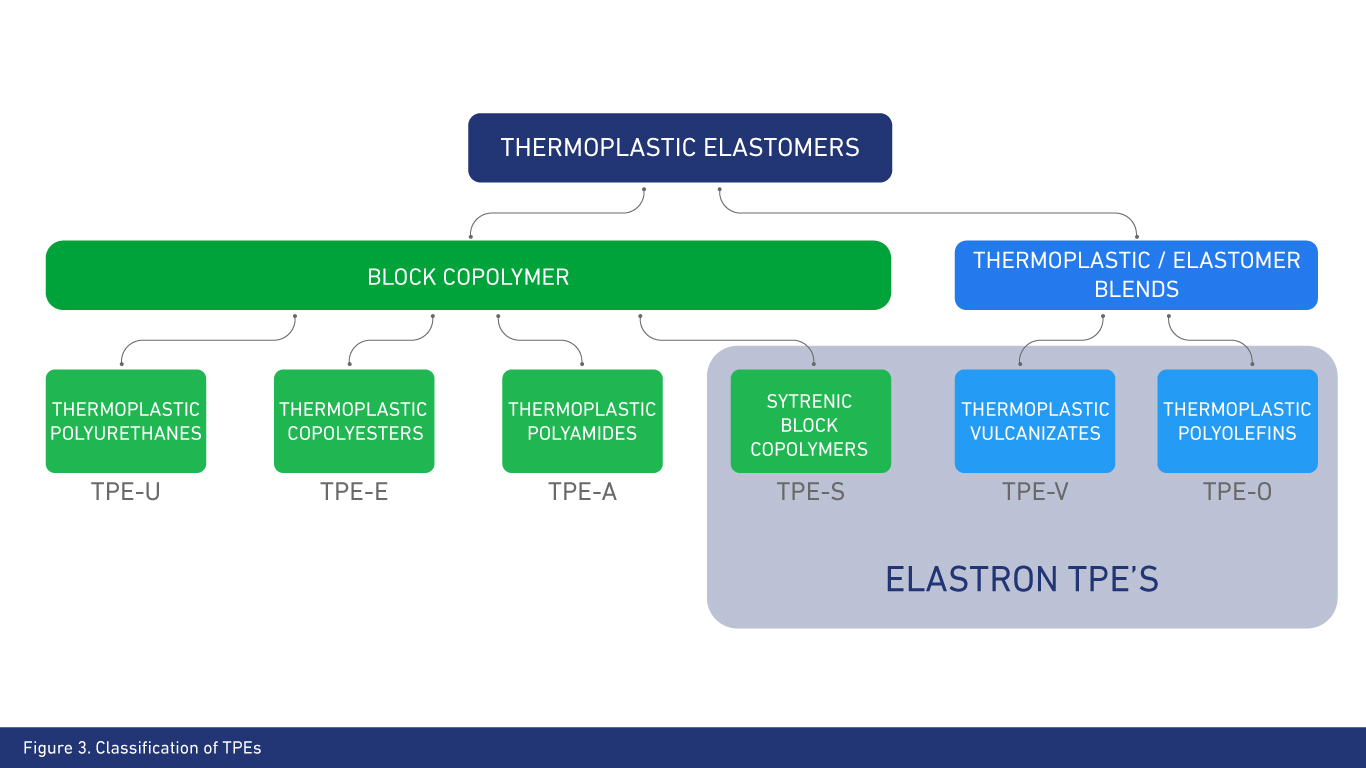

TPEs are classified into two groups as block copolymers or thermoplastic/elastomer blends (Figure 3). Block copolymers are structures containing 2 different monomers in a single polymer chain. Separately, thermoplastic/elastomer blends are formed by mixing elastomer and thermoplastic structure in a molten state.

Morphology of TPEs

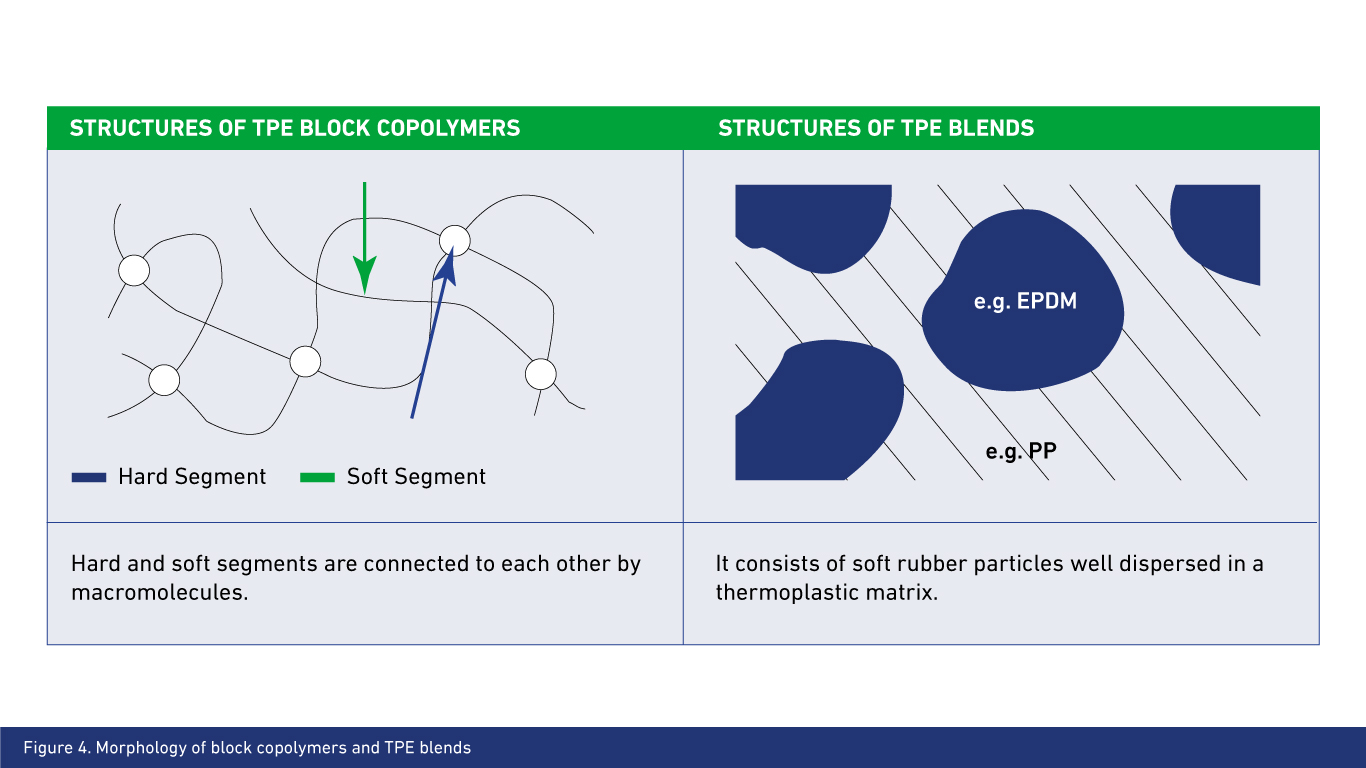

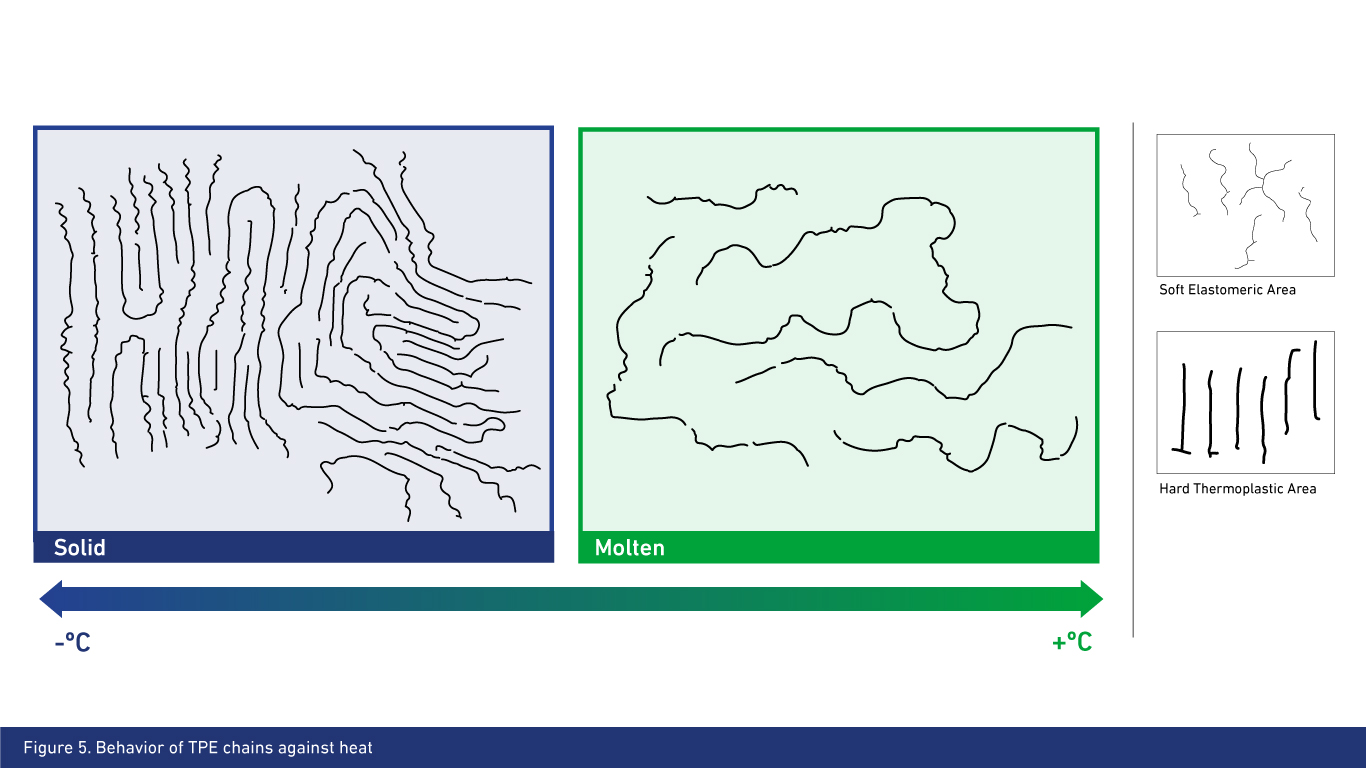

The morphology of TPEs is shown in the two images below.

All TPE varieties contain two or more polymeric phases, one hard and the other soft. When solidified (below the melting temperature), the hard regions of the different chains come together to form hard thermoplastic parts, while the soft regions form elastomeric parts. When a block copolymer is heated above its melting temperature, the bonds between the chains of the hard regions are broken, becoming a molten material suitable for molding, extrusion, or other processing methods (Figure 5). When the molten TPE is cooled down below its melting temperature, the hard regions come together, solidify again and take their final molded form.

Hard segments provide plastic properties

- Mechanical properties (Tensile strength - Modulus - Tear resistance)

- Thermal resistance

- Easy to process

Soft segments provide elastic properties

- Permanent deformation

- Elasticity

- Low heat performance

Advantages of TPEs

- 100% recyclable – no scrap

- Easier processing

- No static crosslinking process

- Shorter cycle time, less energy consumption

- Good coloring

- Processes such as blow molding, thermoforming, heat welding, film blowing can be applied.

- Low density (0.9 g/cm3 )

- Can be colored

Thermoplastic Elastomer Types

Styrene Block Copolymers (SBCs)

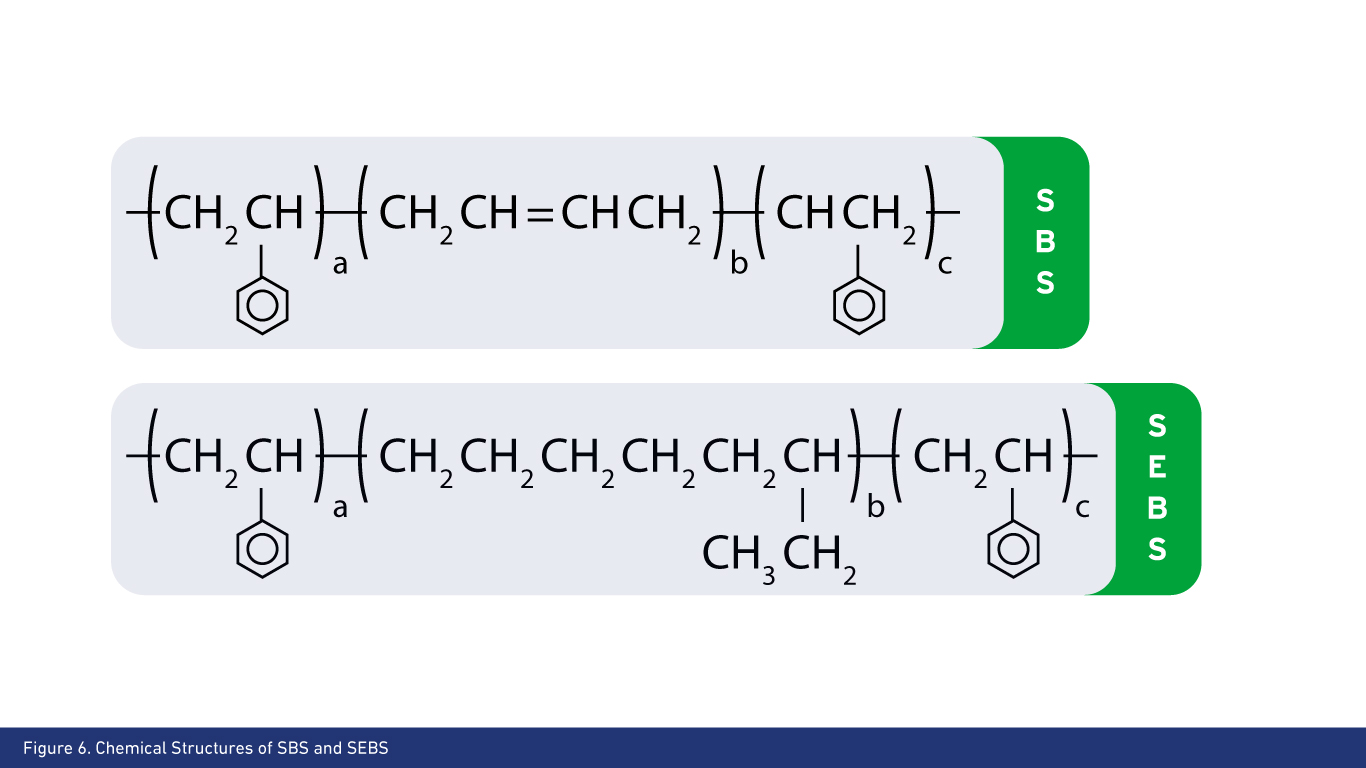

SBCs are multi-phase compounds in a poly (styrene-b-elastomer-b-styrene) structure in which the phases are chemically bonded by block copolymerization. Styrenics are most commonly used among the basic TPE categories. This is because styrenic block copolymers can successfully blend with many materials including fillers, extenders, additives, and other resins.

The properties of the block copolymer vary according to the chemical structure of the elastomer phase. The most commonly used soft phases are butadiene, isoprene, and ethylene-butylene monomers (Figure 6).

Styrene Butadiene Styrene (SBS)

SBS, whose soft phase is butadiene, are not resistant to external conditions due to double bonds in their structures.

Styrene Ethylene Butylene Styrene (SEBS)

On the other hand, SEBS whose soft phase is ethylene butylene, are produced by hydrogenating SBS. They have very good heat, UV, oil, and chemical resistance due to the lack of double bonds in their structures. SEBS is the most commonly used styrenic block copolymer.

Thermoplastic vulcanizates (TPV)

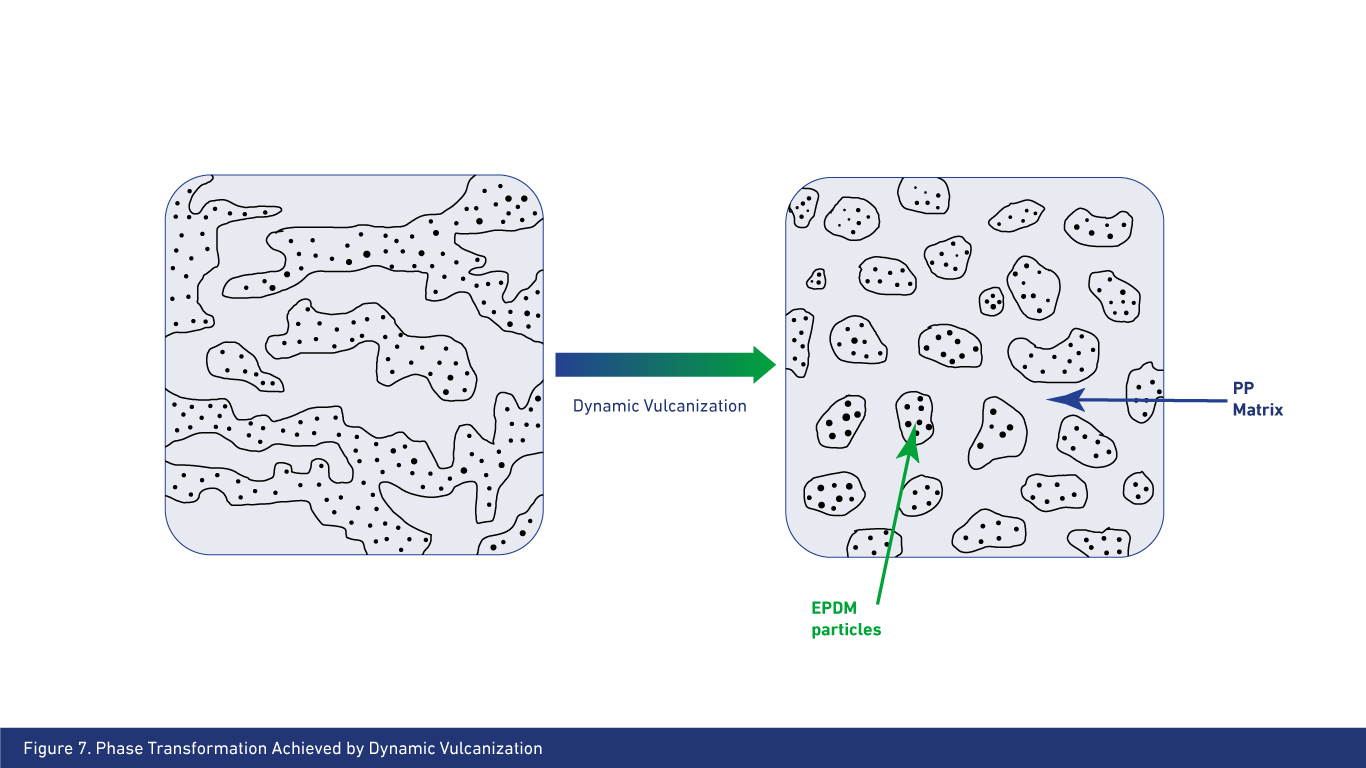

Thermoplastic vulcanizates (TPVs) are formed with homogeneous dispersion of crosslinked rubber parts in the thermoplastic phase through dynamic vulcanization. Dynamic curing refers to the vulcanization or crosslinking of a polymer while mixing with another polymer in the molten state. Unlike static vulcanization, two polymer phases (elastomer and plastic) are required for dynamic vulcanization. Crosslinks and three-dimensional polymer structures are formed in dynamic vulcanization, as in static vulcanization. However, dynamic vulcanization entails the formation of these structures within small rubber particles dispersed in a non-crosslinked thermoplastic matrix. Phase transformation takes place during dynamic vulcanization that enables the formation of structures in this way (Figure 7). Phase transformation is the most important process determining TPV properties.

Most commercial thermoplastic vulcanizates (TPV) are based on a mixture of EPDM and PP. PP is used because it has a high melting point and crystallinity, therefore leading to the formation of TPVs with good properties at high temperatures. On the other hand, EPDM is used because it has a high temperature, oxygen, and ozone stability and subsequently enables the production of TPVs with good heat oxidation and ozone resistance.

Thermoplastic Polyolefins (TPO)

Thermoplastic polyolefins (TPO) are raw materials obtained by the mixing of uncrosslinked amorphous rubbers and semi-crystalline polyolefin thermoplastics in a molten state. Most commercial TPOs are physical mixtures of EPRs and PPs that do not contain double bonds. Production processes do not include a vulcanization step. It stands out with its resistance to impact and chemicals.