TPE Products

Elastron TPE is dedicated to the development, production, marketing and sales of thermoplastic elastomers (TPE) since 1980. With TPV, SEBS and SBS based series; Elastron TPE is the key player in many sectors from beginning to the end.

Thermoplastic Elastomers (TPEs)

Thermoplastic elastomers are defined in the ASTM D1566 standard as "a group of rubber-like materials that, unlike vulcanized conventional rubber materials, can be processed and recycled like thermoplastic materials." Thermoplastic Elastomers do not require curing or vulcanization during processing and can be processed with traditional thermoplastic techniques such as injection molding, extrusion, and blow molding.

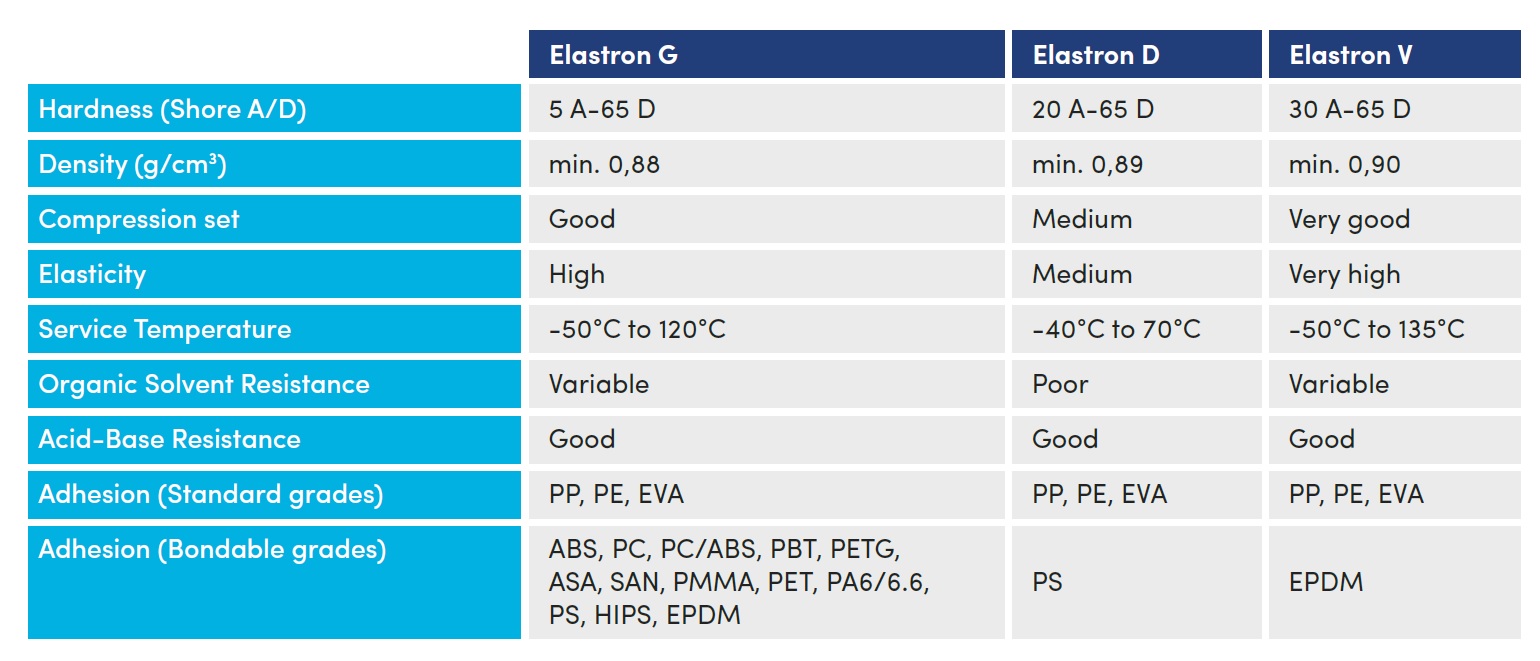

Elastron V (Thermoplastic Vulcanizates)

Thermoplastic vulcanizates (TPVs) are formed by homogeneous dispersion of small crosslinked rubber particles in the thermoplastic phase through dynamic vulcanization.

Thermoplastic vulcanizates (TPVs) are based on a mixture of EPDM and PP. PP is used because it has a high melting point and crystallinity, therefore leading to the formation of TPVs with good properties at high temperatures. On the other hand, EPDM is used because it has a high temperature, oxygen, and ozone stability and subsequently enables the production of TPVs with good heat oxidation and ozone resistance. Other classical benefits of TPVs are chemical resistance to aqueous solutions and low compression set.

Elastron G (SEBS based TPEs)

SEBS based TPE compounds have a soft phase formed by ethylene butylene, and are produced by hydrogenation of SBS. They have very good heat, UV, oil, and chemical resistance due to the lack of double bonds in their structures. SEBS is the most commonly used Styrenic Block Copolymer.

Elastron D (SBS based TPEs)

SBS based TPE compounds have butadiene as the soft phase, and are not as resistant as SEBS based TPE compounds to external conditions due to double bonds in their structures. SBS based TPE compounds are mostly used for indoor applications.