Do you have any questions?

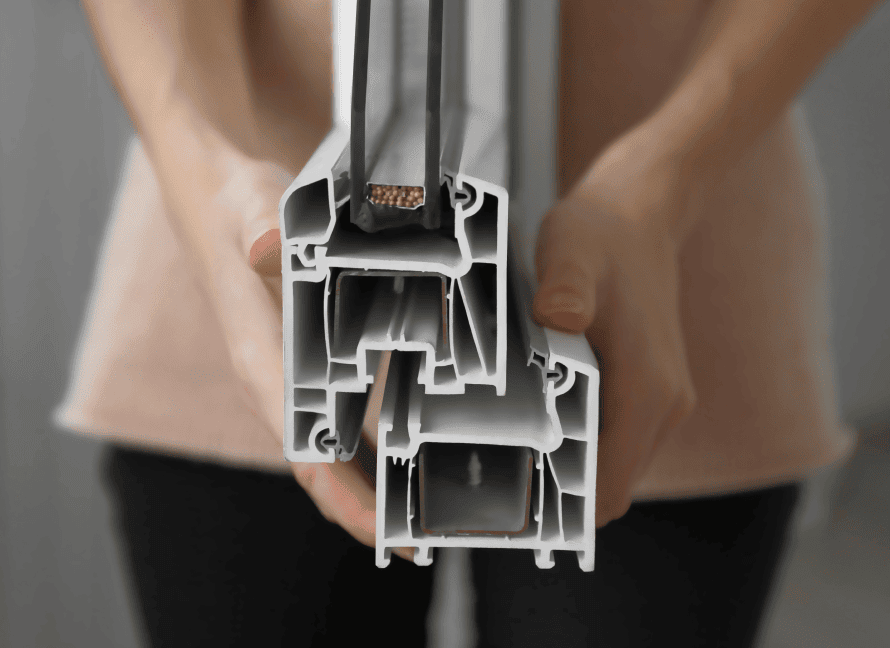

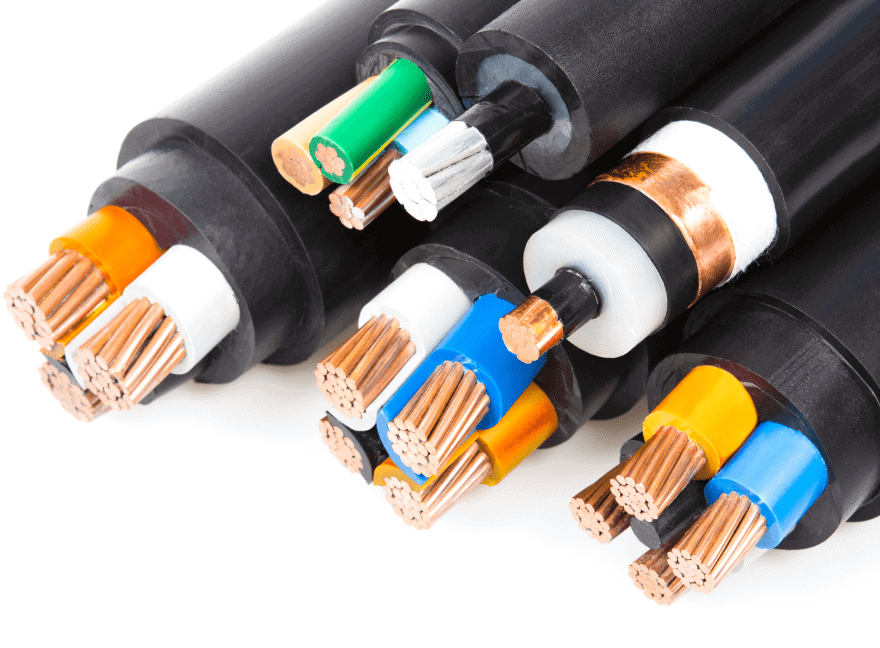

TPV - Elastron V

Elastron V is a thermoplastic vulcanizate (TPV) that introduce a design flexibility, easier processing and recyclability compared to EPDM (ethylene propylene diene monomer) and other thermoset rubber

Advantages of Elastron V

- Service temperature -50°C to 135°C

- Wide hardness range (30 ShA- 65 ShD)

- Lower density (Density changes between 0,90 and 1,12 g/cm³)

- Design flexibility

- UV and ozone resistance

- Weathering resistance

- Provides quite higher saving on the processing cost (less scrap)

- Easy processing with shorter cycle time

- Low compression set

- Recyclable

- Low flex fatigue

- Flame retardant grades available

- Good resistance to acids and bases as well as oils (ex: IRM 903 , IRM 901)

Elastron V101 (General Purpose)

Extrusion & Injection Moulding

Code

Hardness

35A

47A

50A

55A

60A

65A

72A

79A

86A

90A

35D

40D

51D

Density

0,99

0,97

0,97

0,97

0,97

0,97

0,95

0,97

0,97

0,97

0,96

0,96

0,95

Elastron V201 (High Temperature Resistant with Excellent Compression)

Extrusion & Injection Moulding

Code

Hardness

41A

45A

56A

59A

65A

70A

75A

80A

83A

87A

90A

40D

51D

Density

0,97

0,95

0,97

0,97

0,97

0,97

0,97

0,97

0,97

0,96

0,96

0,95

0,95

Elastron V100 (General Purpose)

Injection Moulding

Code

Hardness

50A

55A

60A

65A

70A

75A

85A

40D

55D

Density

0,92

0,97

0,96

0,96

0,96

0,96

0,97

0,90

0,91

Elastron V103 (High Flow)

Elastron V250 & V251 (Automotive Weatherseal)

Elastron V206 (Low Coefficent of Friction)

Elastron P.V101 (Medical)

Extrusion & Injection Moulding

Code

Hardness

30A

40A

45A

50A

55A

60A

64A

70A

80A

90A

40D

Density

0,90

0,90

0,90

0,90

0,90

0,92

0,92

0,91

0,91

0,91

0,91

Elastron V601 (Halogen Free Flame Retardant)

Extrusion & Injection Moulding

Code

Hardness

60A

65A

70A

80A

90A

93A

95A

Density

1,12

1,12

1,12

1,12

1,12

1,12

1,12